Each type of plastic material has distinct characteristics. Therefore, when selecting materials for a product, it's essential to choose the most suitable one based on the material's features and its intended use.

Before selecting a material, we need to understand the basic properties of various plastic materials to ensure we make the most appropriate choice for the finished product.

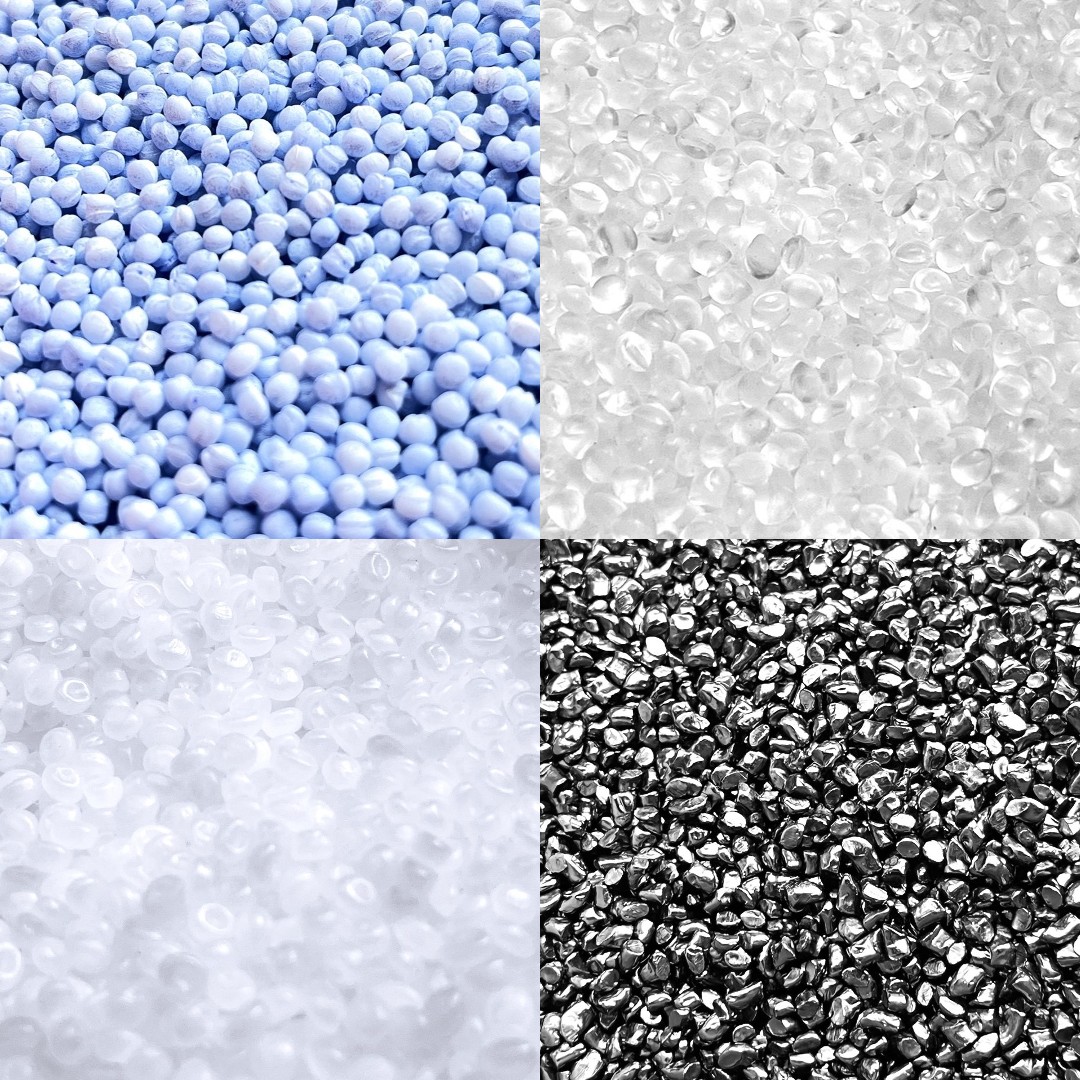

— Plastic Raw Material

We have organized a table based on factors like the specific gravity, deformation temperature, flammability, advantages and disadvantages, and uses of different plastic materials. Please see below (arranged in A to Z):

| Properties and Applications of Plastic Materials | ||||||

| Material | Weight | Shape Against Temperature | Nature of Flame | Properties | Applications | |

| Advantages | Disadvantages | |||||

| ABS | 0.99-1.10 | 95-112°C (4.6-kg/cm²) | ○ | 1. Good appearance and physical properties 2. Excellent plating characteristics 3. Superior impact resistance at low temperatures 4. Low molding shrinkage rate, with high dimensional accuracy 5. Good anti-acid/base | 1. Poor weather resistance 2. Soluble in solvents |

1. Industrial goods 2. Automotive products 3. Household goods |

| NYLON | N6: 1.12-1.14 N66: 1.13-1.15 | 127-171°C (4.6-kg/cm²) 149-182°C (4.6-kg/cm²) | ╳ | 1. Tough, impact-resistant 2. Self-lubricating, high friction resistance 3. Excellent heat and cold resistance 4. Good chemical and oil resistance | 1. High water absorption, lacks dimensional stability 2. Weak resistance to strong acids |

1. Car Parts 2. Sturdy Items 3. Water Pipes 4. Tubes |

| PBT |

1.31-1.38 | 155-160°C (4.6-kg/cm²) | ╳ | 1. Tough and Impact Resistant 2. Excellent Heat Resistance 3. Good Weather Resistance 4. Self-Lubricating, High Friction Resistance 5. Low Water Absorption, Excellent Dimensional Stability | 1. Poor Alkali Resistance 2. Poor Hot Water Resistance |

1. Electrical Appliances 2. Mechanical Products 3. Construction Materials 4. Daily Miscellaneous Goods |

| PC | 1.25-1.25 | - | ╳ | 1. Tough and Impact Resistant 2. Excellent Heat and Cold Resistance 3. High Dimensional Accuracy and Stability 4. Good Weather Resistance 5. Transparent | 1. Poor Fatigue Resistance 2. Weak UV Resistance 3. Weak Alkali Resistance | 1. Mechanical Parts Requiring Various Loads 2. Heat-Resistant Electrical Appliances 3. Automotive Parts 4. Construction Materials 5. Metal Substitutes |

| PE |

HDPE: 0.95-0.96 LDPE: 0.92-0.94 | 60-82°C (4.6-kg/cm²) 41-49°C (4.6-kg/cm²) | ○ | 1. Excellent Cold Resistance 2. Hygienic and Non-toxic 3. Good Water and Chemical Resistance 4. Excellent Electrical Properties 5. High Flexibility | 1. Poor Heat Resistance 2. High Molding Shrinkage |

1. Various Sealed Containers 2. Packaging Bags 3. Toys 4. Kitchen Utensils 5. Mechanical Parts |

| PU | 1.11-1.24 | Soften point 100-160°C | ○ | 1. Good Weather Resistance 2. High Cold Resistance (-35°C~50°C) 3. Excellent Oxidation Resistance 4. Adjustable Softness and Hardness | 1. Low softness, prone to mold sticking and shrinkage 2. Raw material requires long drying time |

1. Footwear, sports goods 2. Household appliances and electrical insulation 3. Soft-touch handles, armrests |

| POM | 1.41-1.43 | Homopolymer 160-170°C | ○ | 1. Tough and Elastic 2. Clip Characteristics, Excellent Fatigue Resistance 3. Self-lubricating, High Friction Resistance 4. Chemical Resistance 5. Excellent Heat Resistance | 1. Weak UV resistance 2. Thermal decomposition and formalin gas emission 3. Weak resistance to strong acids | 1. Industrial goods that require load-bearing 2. Automotive and electrical goods 3. Toy products 4. Metal substitutes |

| PMMA | 1.18-1.19 | 71-91°C (4.6-kg/cm²) | ○ | 1. Excellent Transparency 2. Excellent Weather Resistance 3. Good Moldability 4. Good Electrical Properties | 1. Poor Impact Resistance 2. Soluble in Solvents |

1. Industrial materials replacing glass (e.g., watches) 2. Contact lenses 3. Decorative items 4. Electrical appliances (e.g., lighting fixtures) |

| PP | 0.90-0.92 | 99-110°C (4.6-kg/cm²) | ○ | 1. Excellent Toughness 2. Excellent Heat Resistance 3. Lightest among plastics 4. Excellent Electrical Properties | 1. Poor Impact Resistance at Low Temperatures 2. Poor Weather Resistance |

1. Various heat-resistant containers 2. Film 3. Toys 4. Pipes, Boards 5. Heat-resistant industrial products |

| PS | 1.03-1.07 | 82-104°C (4.6-kg/cm²) | ○ | 1. Good Molding Properties 2. Excellent Rigidity and Surface Hardness 3. Excellent Transparency 4. Excellent Electrical Properties 5. Good Acid and Alkali Resistance | 1. Poor Impact Resistance 2. Poor Heat Resistance 3. Soluble in Solvents |

1. Electrical products 2. Toys 3. Boards 4. Daily goods |

| PVC | H.PVC: 1.16-1.45 S.PVC: 1.32-1.70 | 62-72°C (4.6-kg/cm²) | ╳ | 1. Good Molding Properties 2. Hard and Tough 3. Excellent Weather Resistance 4. Excellent Water Resistance 5. Excellent Chemical 6. Resistance Affordable Price | 1. Poor Heat and Cold Resistance 2. Poor Impact Resistance 3. Poor Twisting Resistance |

1. Pipes and pipe fittings 2. Wire insulation 3. Footwear 4. Industrial and special chemical products 5. Imitation leather 6. Film |

| TPE | 1.15-1.24 | Soften point 100-160°C | ○ | 1. Soft Texture and Elasticity 2. Excellent Weather Resistance 3. Cold Resistance up to -40°C | 1. Poor Dyeing Performance | 1. Cushioning, soundproofing, vibration absorption products 2. Footwear, sports equipment 3. Electrical insulation for household appliances and electronics |

We hope that this information can help you understand Plastic Raw Material better.

If you have any other process control, mold design or other questions, please feel free to contact us.

We are professional Kayak Accessories and Bag Accessories Manufacturer in Taiwan, please contact us if you have any needs for Kayak Accessories or Plastic Injection Molding Service.

Email: sales@broadplast.com

Find us elsewhere: Where to Find Us?